Flat Top Vibrating Screen - www.alexwiremesh.com

The product Flat Top Vibrating Screen appeared first on Alex Wire Mesh.

manager@alexwiremesh.com

manager@alexwiremesh.com

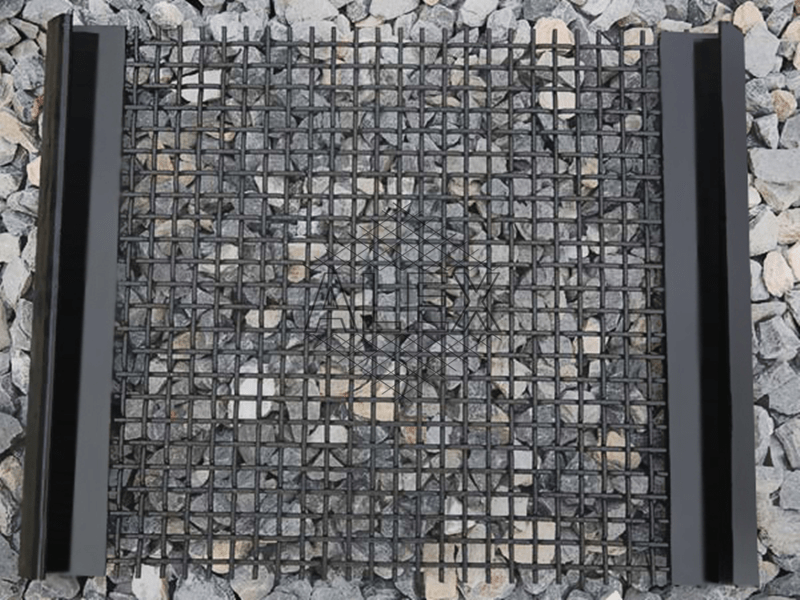

Structural Advantage

- (1) Flat top vibrating screen offers a tight and smooth surface for stable material separation.

- (2) It maintains uniform opening with no loose joint.

- (3) It prevents snagging or clogging during operation.

- (4) It enhances wear resistance through flattened wire contact.

- (5) It increases open area without reducing support strength.

- (6) It improves tension stability over extended duration.

- (7) It delivers precise screening through flat wire profile.

- (8) This wire mesh simplifies frame attachment due to even alignment.

Specification

- (1) Wire diameter: 0.71mm – 12.5mm

- (2) Mesh size: 1mm – 100mm

- (3) Hole type: square, rectangular and long slot

- (4) Max. width: 2.2m

- (5) Max. length: 5m (+/-2mm) for panel or 50m (+/-2mm) for roll

Surface Design Impact

- (1) Flat top vibrating screen features a leveled screening surface.

- (2) It reduces turbulence and material bounce.

- (3) It allows quiet operation in sensitive zone.

- (4) It protects fragile material during handling.

- (5) It provides a predictable flow path.

- (6) It prevents angular wear on the mesh face.

- (7) It enhances visual inspection ease.

- (8) This wire net resists deformation during vibration cycles.

Application Suitability

- (1) This wire screen fits quarry, mining, and industrial setting.

- (2) It operates reliably in dry or wet condition.

- (3) It handles gravel, sand, coal, and mineral.

- (4) It suits fine, medium, and coarse separation.

- (5) It supports conveyor-fed or hopper-fed layout.

- (6) It functions well in high-frequency screening.

- (7) It integrates seamlessly into linear motion system.

- (8) This screen mesh complements rotary screen without conflict.

Material Selection Value

- (1) Flat top vibrating screen uses steel or stainless steel option.

- (2) It provides rust resistance for outdoor operation.

- (3) It handles abrasive material with minimal wear.

- (4) It prevents material contamination during use.

- (5) It keeps original shape even under pressure.

- (6) It maintains integrity under thermal variation.

- (7) It suits food, chemical, and mining process.

- (8) This screen mesh minimizes replacement frequency over time.

Comments

Post a Comment