Polyurethane Vibrating Screen - www.alexwiremesh.com

The product Polyurethane Vibrating Screen appeared first on Alex Wire Mesh.

manager@alexwiremesh.com

manager@alexwiremesh.com

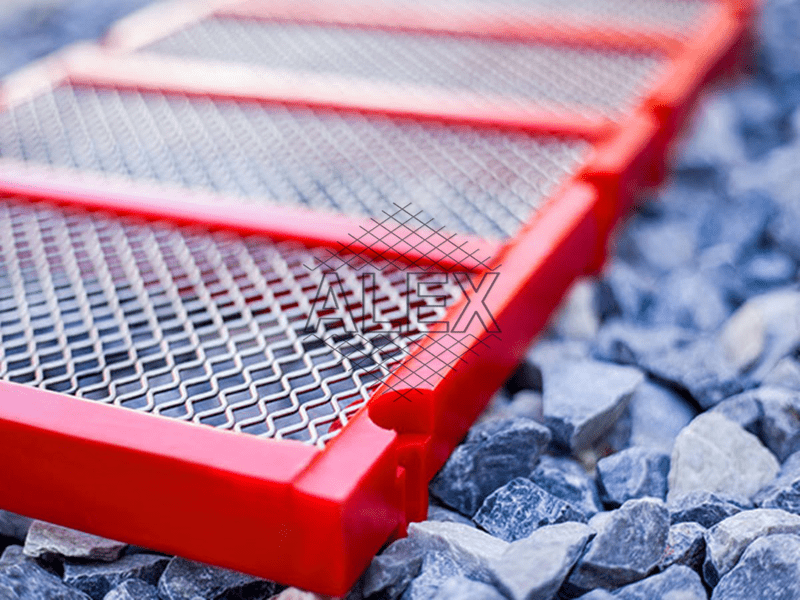

Structural Integrity

- (1) Polyurethane vibrating screen is engineered for reliable support under extreme stress.

- (2) It prevents bending in high-vibration application.

- (3) It supports long usage without cracking.

- (4) It avoids shape distortion from heavy load.

- (5) It strengthens each connection point.

- (6) It resists fatigue from rapid movement.

- (7) It maintains rigidity in dynamic condition.

- (8) This screen mesh assures safety through stable design.

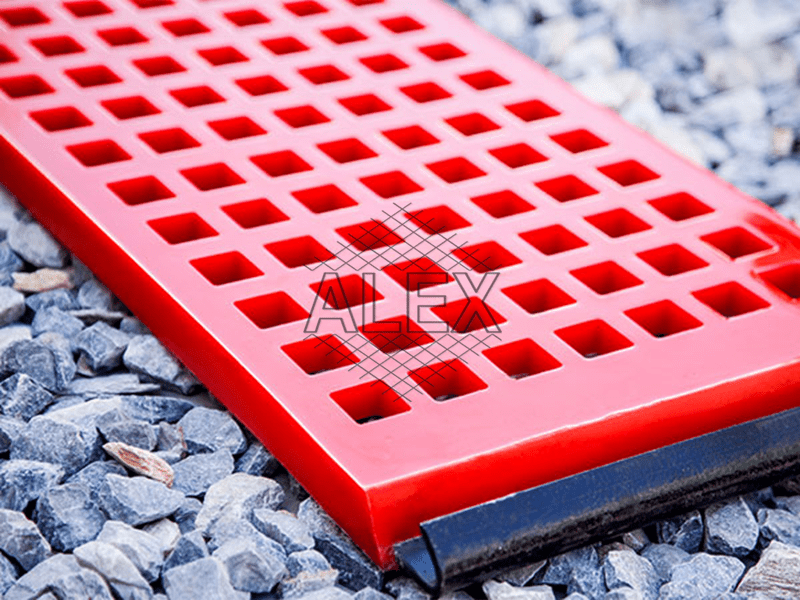

Specification

- (1) Material: Steel wire inside, polyurethane coated outside

- (2) Opening: 0.6mm-160mm

- (3) Screen thickness: 20mm-60mm

- (4) Standard width: 150mm or 300mm

- (5) Max. length: 1200mm

- (6) Opening types: Comb, square, oblong, round

- (7) Join types: Mosaic, bolt, layering connection or hooks

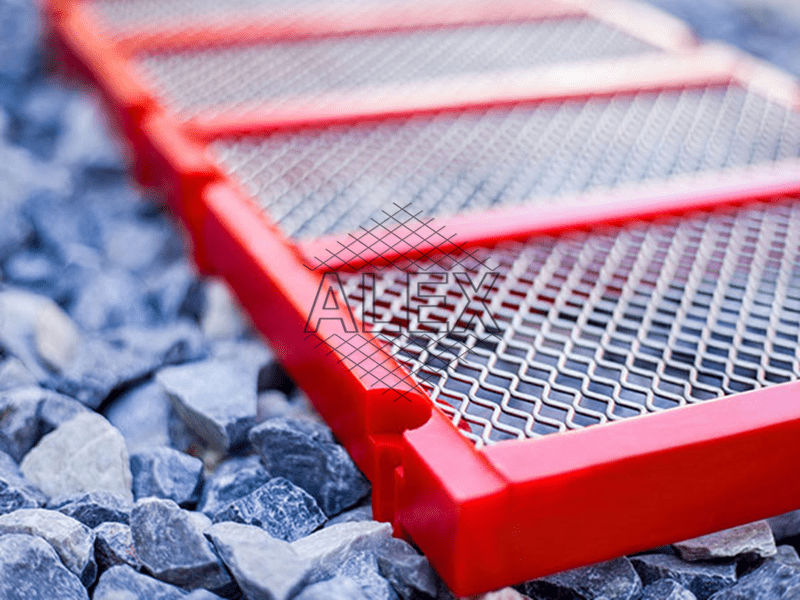

Anti-Clogging Performance

- (1) Polyurethane vibrating screen is built to resist particle blockage in wet screening.

- (2) It clears residue using self-cleaning surface.

- (3) It allows material flow without delay.

- (4) It reduces downtime caused by jam.

- (5) It limits production loss in sticky condition.

- (6) It keeps performance stable under sludge.

- (7) It protects mesh from pressure buildup.

- (8) This wire screen delivers cleaner separation continuously.

Environmental Suitability

- (1) This wire mesh is ideal for outdoor and harsh climate application.

- (2) It withstands sun exposure without fading.

- (3) It performs in snow without cracking.

- (4) It tolerates chemical spray near process line.

- (5) It prevents UV damage during daily use.

- (6) It operates under wind, heat, or humidity.

- (7) It avoids wear from dust impact.

- (8) It adapts to different working environments.

Customization Option

- (1) Polyurethane vibrating screen is available in different size and shape for exact application.

- (2) It accepts special requirement from customer.

- (3) It adjusts layout for machine compatibility.

- (4) It integrates color coding for safety.

- (5) It supports branding through surface print.

- (6) It changes hole pattern to meet task.

- (7) It modifies thickness as needed.

- (8) This wire net offers precise match with project design.

Comments

Post a Comment