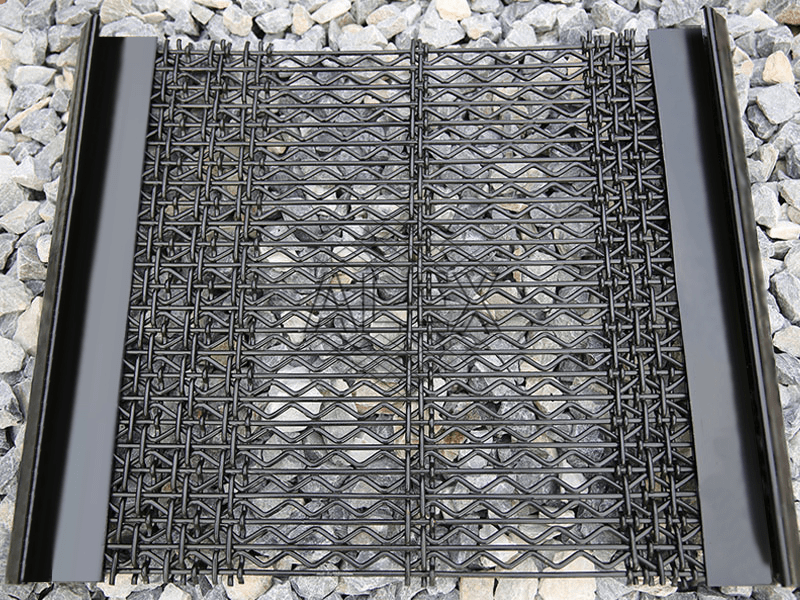

Self Cleaning Vibrating Screen - www.alexwiremesh.com

The product Self Cleaning Vibrating Screen appeared first on Alex Wire Mesh.

manager@alexwiremesh.com

manager@alexwiremesh.com

Material Compatibility

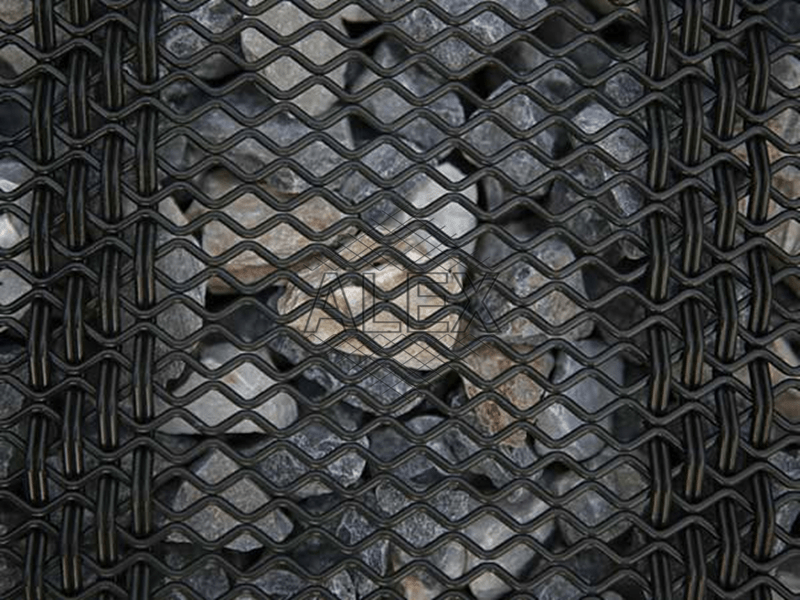

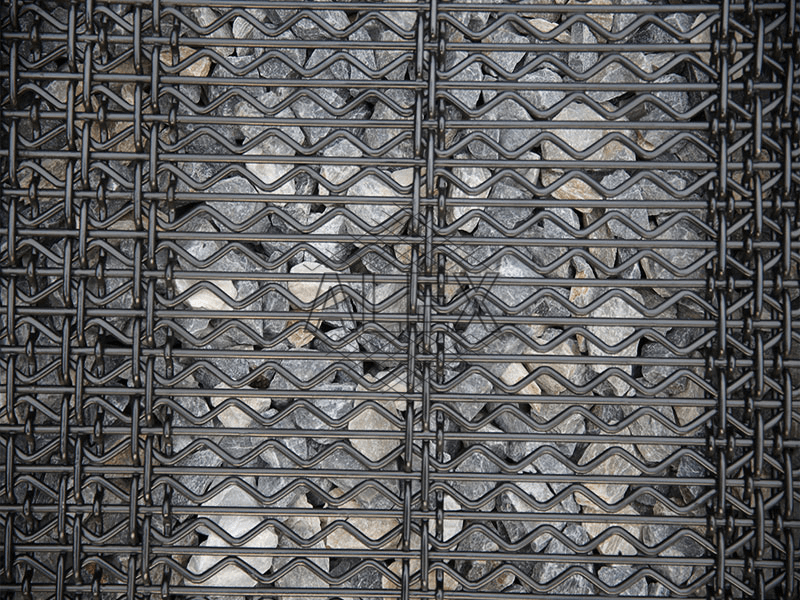

- (1) Self cleaning vibrating screen supports abrasive mineral material.

- (2) It handles sticky clay without screen blockage.

- (3) It resists damage when processing coal and ore.

- (4) It adapts to organic input like biomass or compost.

- (5) It filters polymer material during plastic processing.

- (6) It screens damp limestone under high humidity.

- (7) It tolerates soft powder without loss of accuracy.

- (8) This wire mesh manages crushed glass with sharp edges effectively.

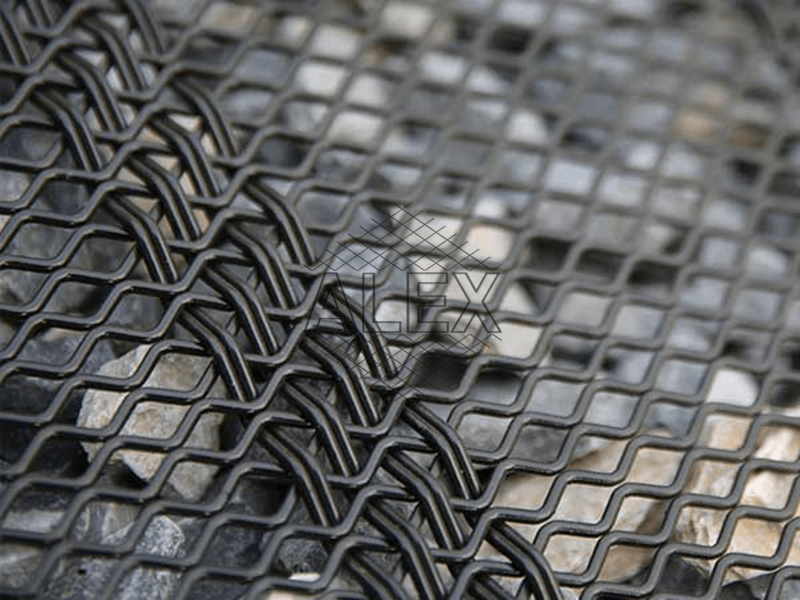

Specification

- (1) Material: High tensile steel wire (5#, 55#,65#, 65Mn) or stainless steel wire (304, 316, 316L)

- (2) Wire diameter: 1.2mm-6mm

- (3) Max width: As required

- (4) Max length: As required

Installation Environment

- (1) Self cleaning vibrating screen fits confined workstations easily.

- (2) It withstands offshore screening under corrosive conditions.

- (3) It operates in mobile units during field operations.

- (4) It installs indoors for controlled production settings.

- (5) It functions near conveyors without structural interference.

- (6) It avoids dust accumulation in enclosed spaces.

- (7) It connects to silos using minimal pipework.

- (8) This wire net allows height adjustment for uneven flooring.

Customization Option

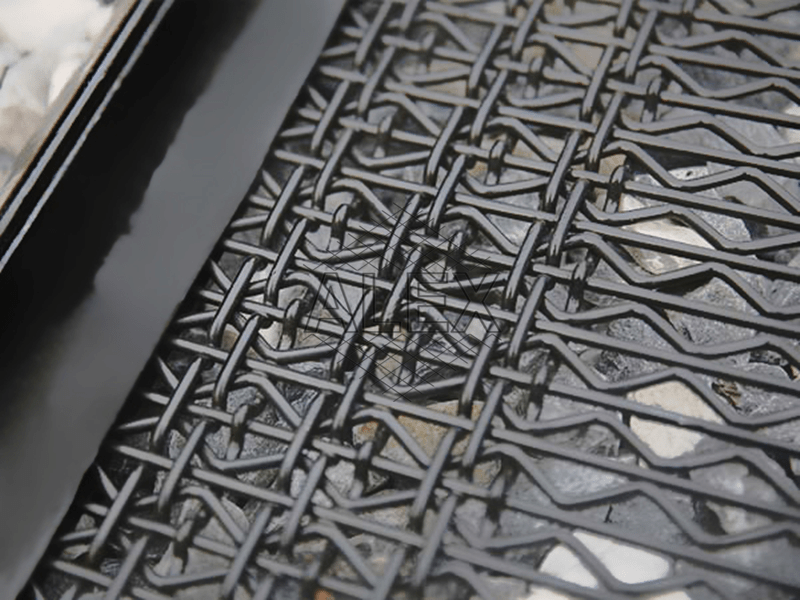

- (1) This wire screen screen accepts modular frame design.

- (2) It matches drive power to screening load.

- (3) It fits specialized deck shapes for rare material.

- (4) It integrates single-wire configuration on request.

- (5) It aligns with unique feed inlet requirements.

- (6) It adjusts vibration angle for custom flow speed.

- (7) It uses tailored screen tension for tight precision.

- (8) It allows paint finish based on industry needs.

Noise Reduction

- (1) Self cleaning vibrating screen controls vibration resonance effectively.

- (2) It minimizes noise using balanced weight design.

- (3) It incorporates rubber mounts to absorb shock.

- (4) It avoids high-frequency echo inside steel units.

- (5) It applies coating that dampens metallic vibration.

- (6) It operates below industrial noise standards.

- (7) It reduces sound disturbance near offices.

- (8) This screen mesh creates a quiet environment for quality control.

Comments

Post a Comment